SWARM-EX

Mechanical Design of a CubeSat

Mechanical Design of a CubeSat

This summer (2021) I was offered the chance to work with a team of students from Stanford, Georgia Tech, Colorado Boulder, South Alabama, Western Michigan, and my own Olin College to design a CubeSat. The project, known as SWARM-EX, involves making three CubeSats that will launch in 2023 and fly together to collect atmospheric data. I worked under Olin's OSSTP group on the mechanical design of the CubeSat.

While I had some prior experience in aero, designing and flying planes, I had only ever researched spacecraft and never been involved in designing one. This was a new experience for me.

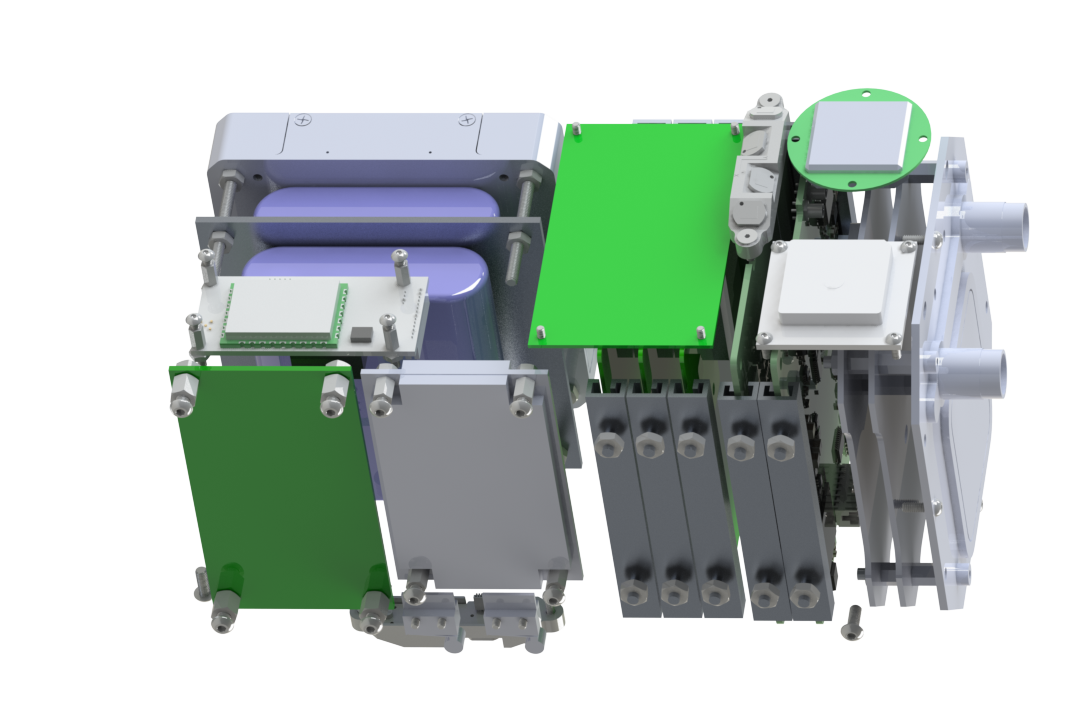

During my time on the SWARM-EX project this summer, I designed the first iteration of the CubeSat structure to be machined. This involved lots of time in Solidworks, and collaborating with other subteams to fit all the modules in the structure. It was like playing a 3D game of Tetris with high stakes.

While I spent most of my time on mechanical design, working with groups from the other Universities gave me insight into how each component of a CubeSat works, from propulsion to communications to power systems. It was also great to meet new people and understand a variety of perspectives and challenges.

I have enjoyed working with the OSSTP and SWARM-EX groups and will be continuing part time in the fall! You can see some of my work this summer below!

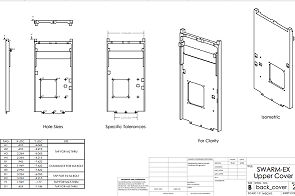

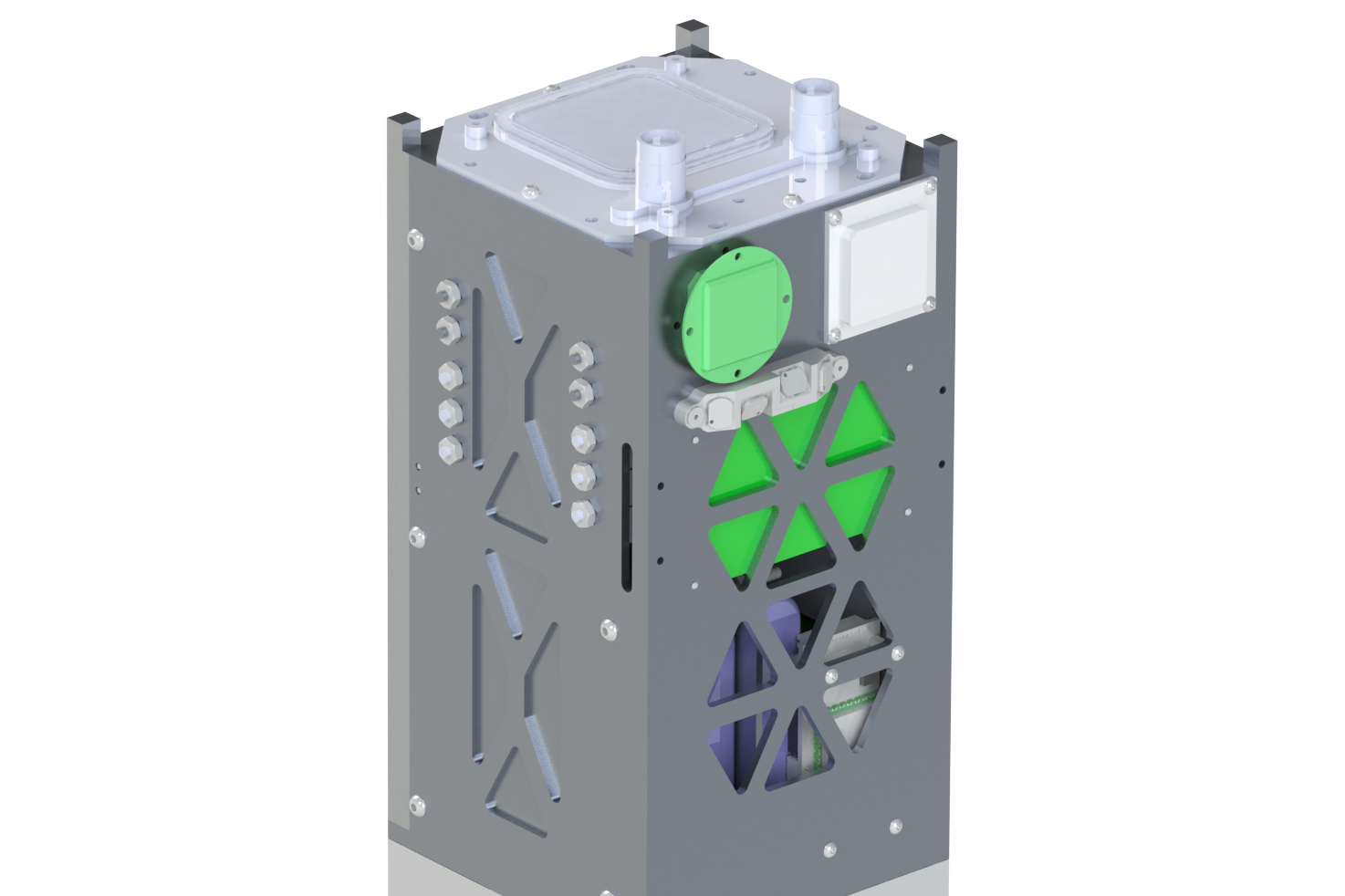

Upper structure of the CubeSat, made from

6061 aluminum. The cover can be detached

to access modules.

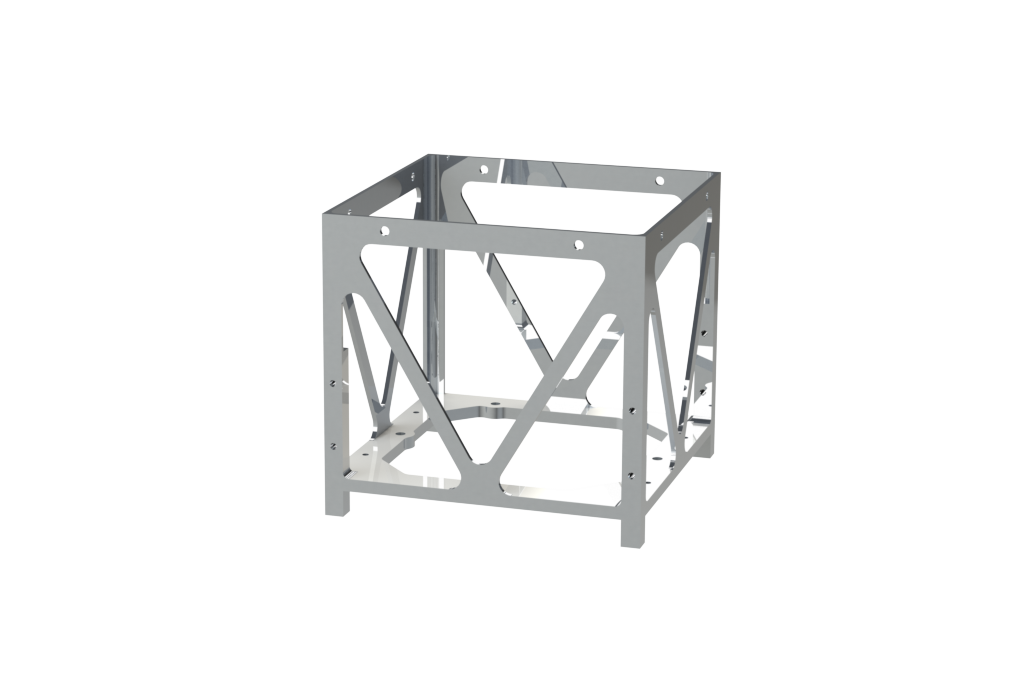

The lower structure houses the propulsion

module and is also made of 6061.

The inside of the CubeSat has many modules

that fit compactly together.

The CubeSat was machined according to

mechanical drawings that we made.

Both structures have light weighting

and room to mount antennas.

This past semester, Tigey has jumped right in to working on and the NSF funded multi-institutional university smallsat mission, SWARM- EX. As a member of the SWARM-EX team, Tigey utilized SolidWorks to perform exceptional mechanical design and design for manufacturing of the small satellites and their components. Tigey maintained professional communication and patience when working alongside individuals across the country, at different institutions, on different subsystems to manage and ensure that their subsystems fit their modules into the small satellites. Tigey is incredibly organized and thorough in all that he endeavors to pursue. I have no doubt that Tigey will be successful in his career and meaningfully contribute to the aerospace and mechanical industry!

- Whitney Lohmeyer