Practical Scientific Solutions

An internship in mechanical design and creativity

An internship in mechanical design and creativity

The summer after my freshmen year at college, I got an internship at a small company called Practical Scientific Solutions. Being my first full internship position, I didn't know what to expect.

I started with some projects focused around developing a device design to the point where it could be manufactured, according to various specifications. My Solidworks skills greatly improved and I learned how to choose mechanical, electrical, and material parts based on design constraints and budget.

I also worked on several research projects that involved much earlier stage planning and design. While technically easier, these projects were tough as they were more open-ended and the goal was much less clearly set. Examples include a feasibility study on the use of radio and inertial tracking systems utilizing dead reckoning in comparison to GPS, and research into the cost, technical, and logistical aspects of launching a cubesat. These projects taught me how to deal with open ended work and gave me a better sense of when such a project is done or needs more work.

I really enjoyed working at Practical Scientific! You can see some examples of my work below.

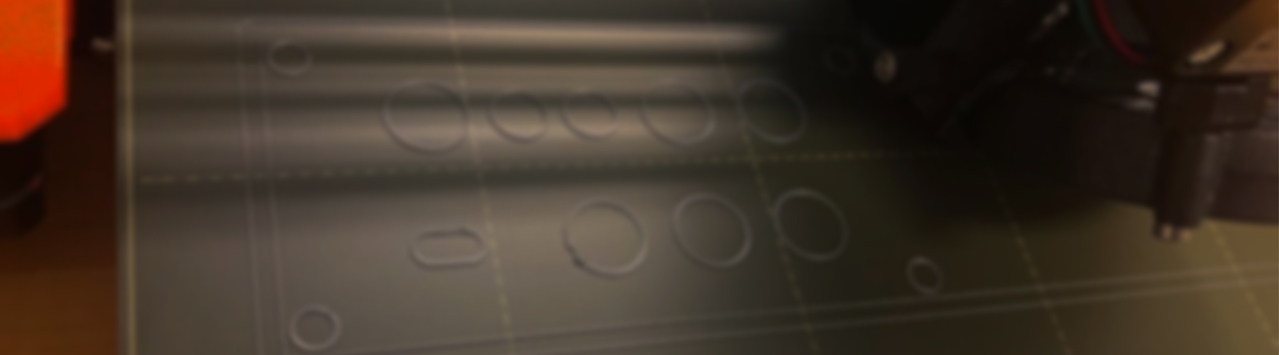

Front view of box designed to emit colored light.

Design also includes a removable inner tray

for easy 3D printing and a rugged frame.

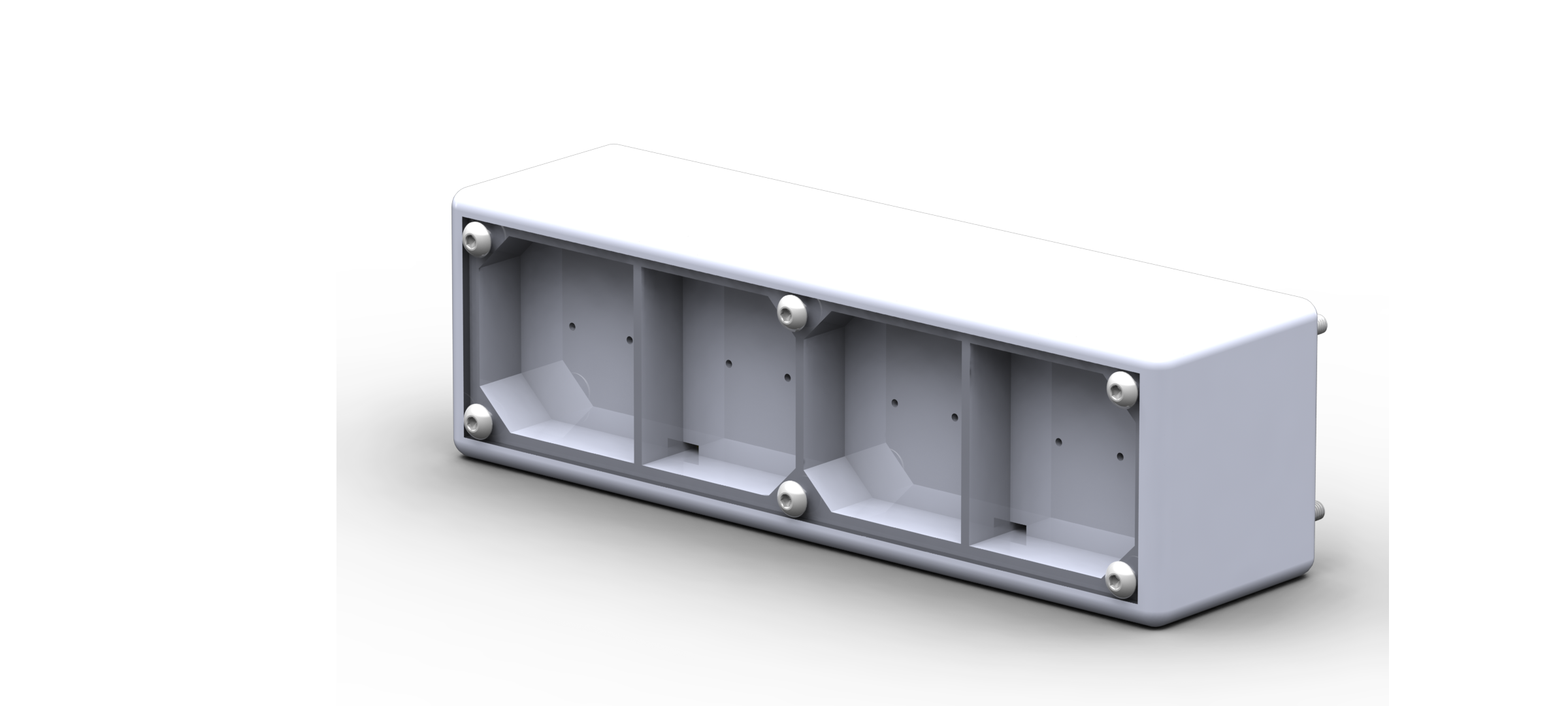

Exploded view of box. Designed for use with various

electronics and COTS parts for cost effectiveness

and simple assembly.

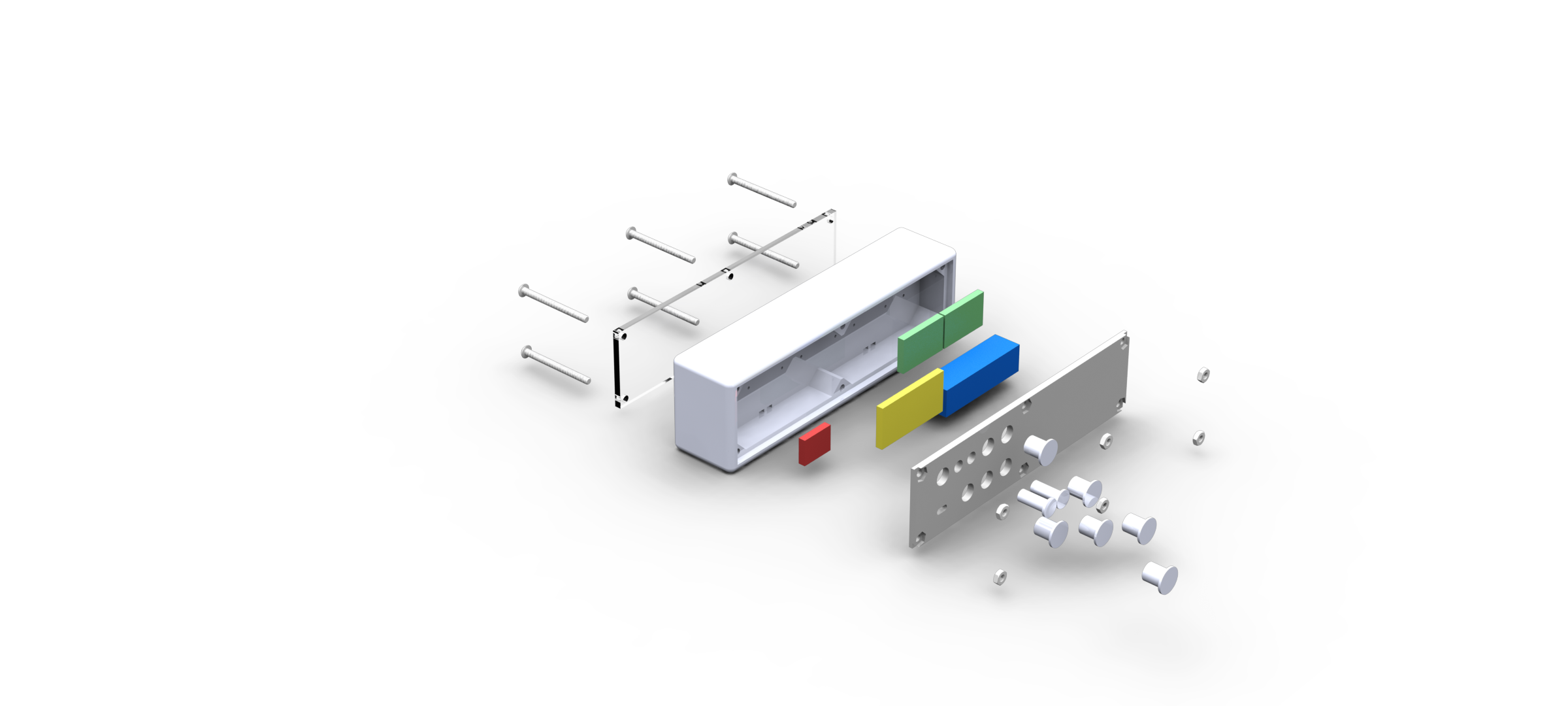

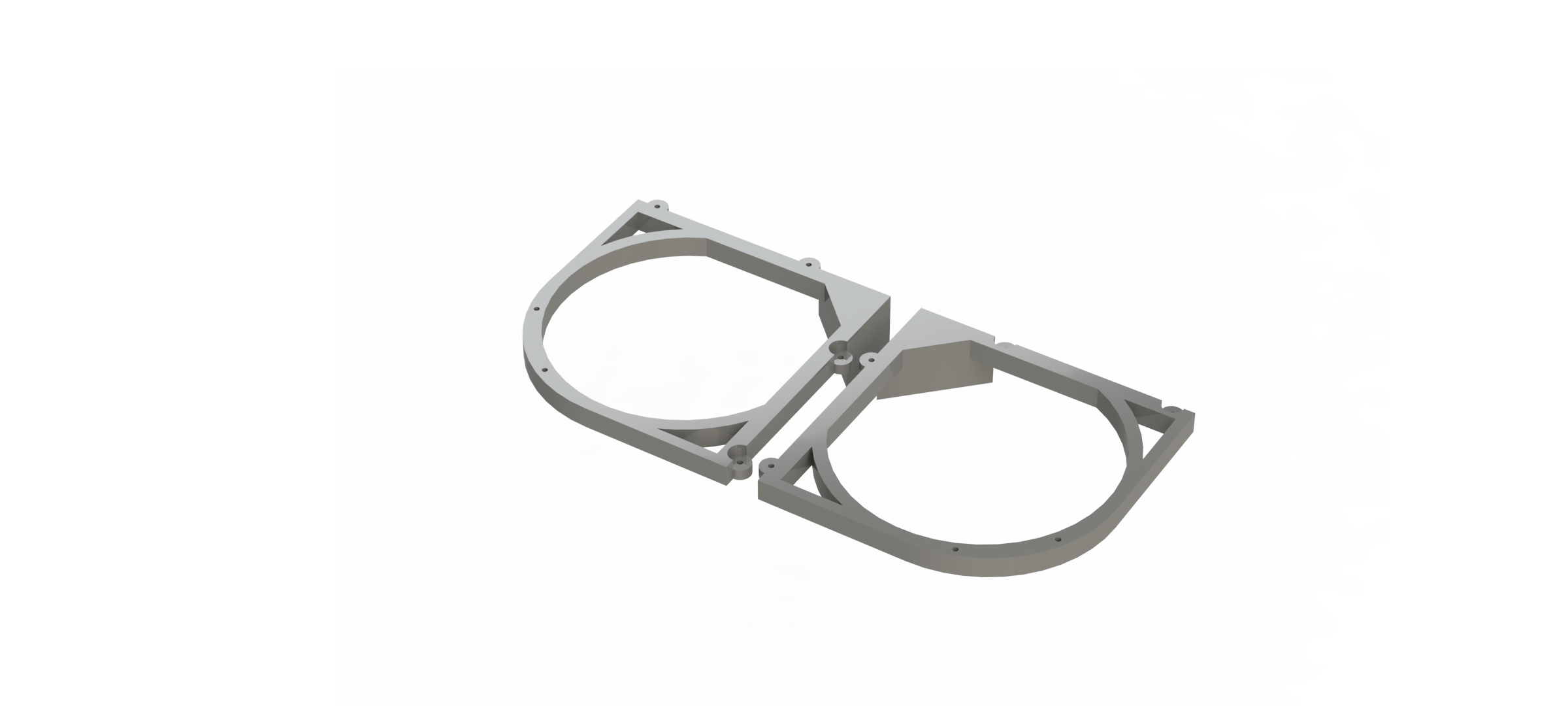

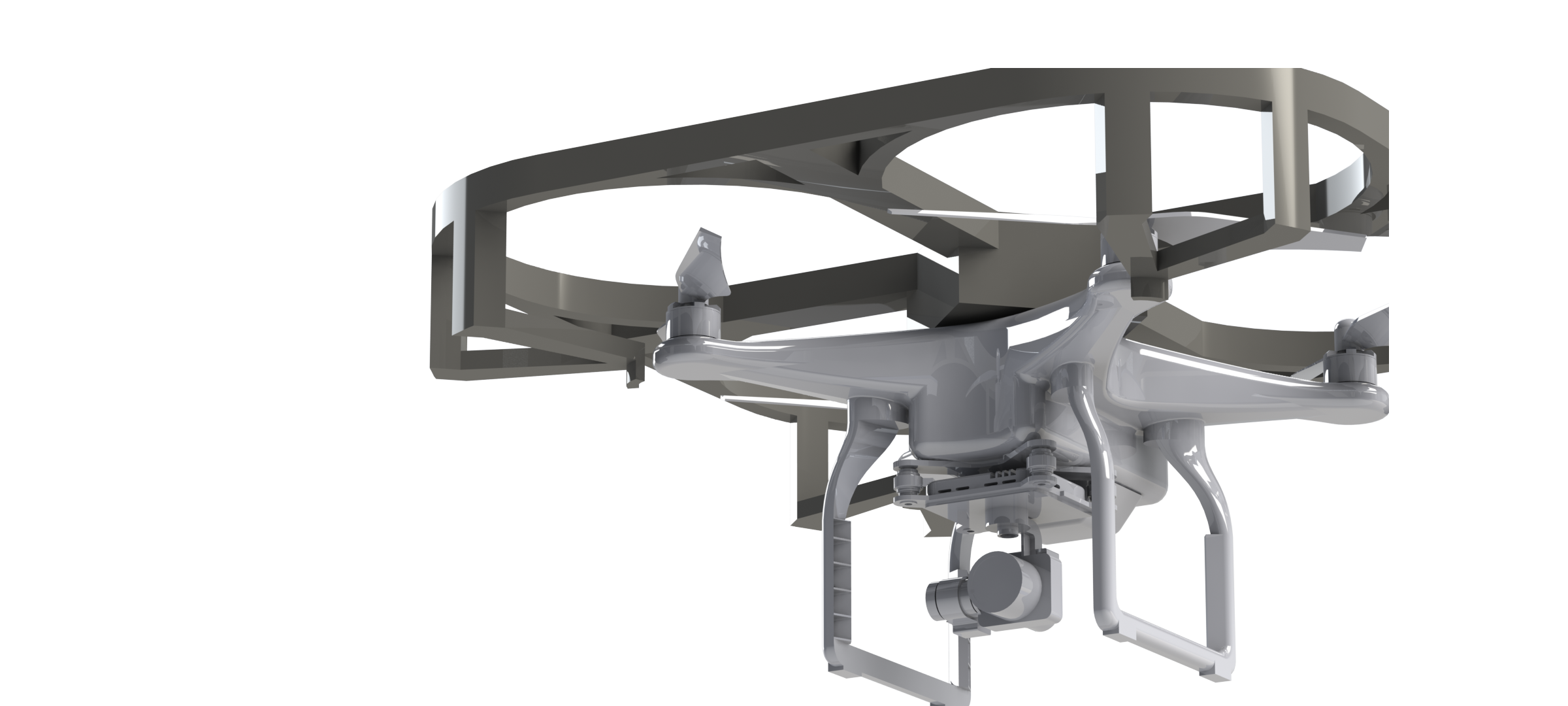

The drone protection system, designed to

easily disassemble yet remain durable

Full top drone protection

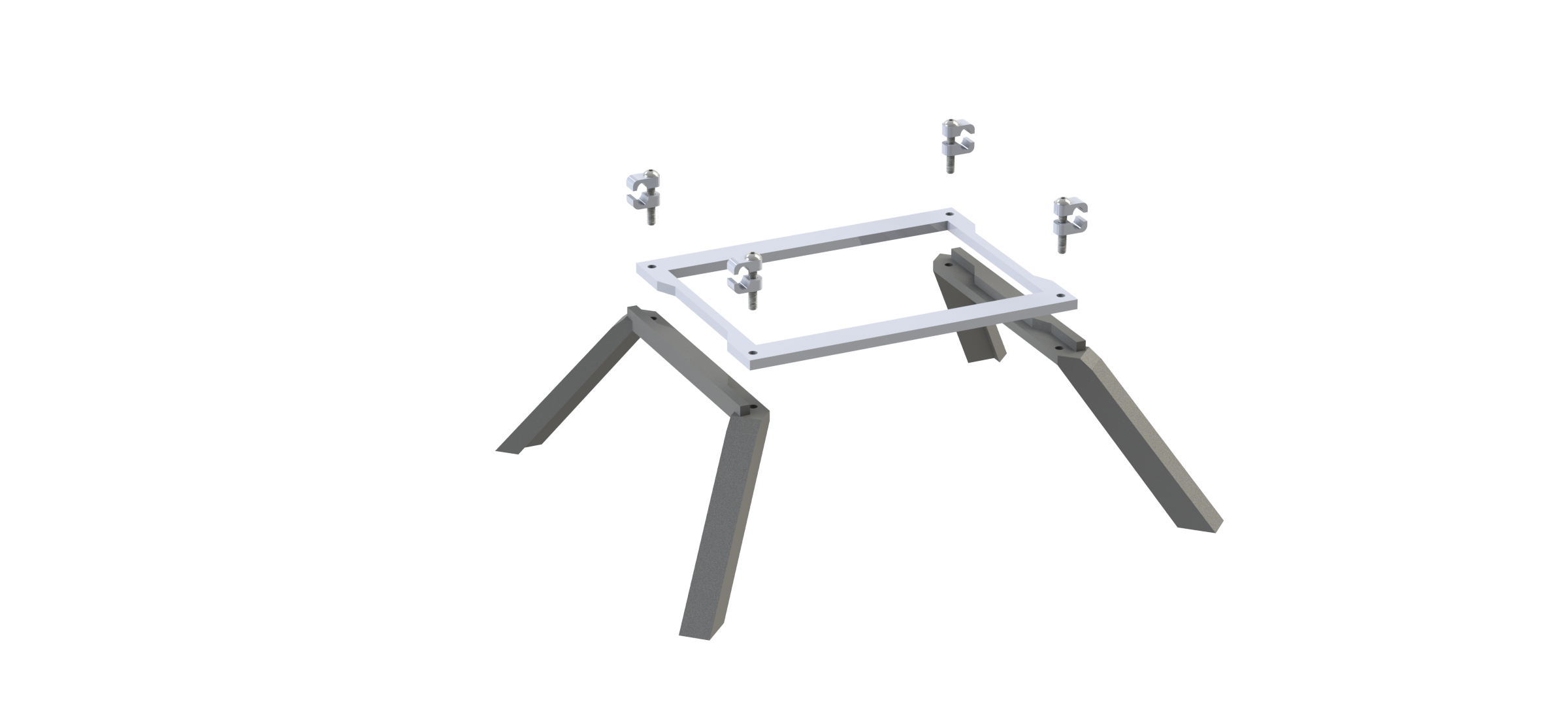

Extended landing gear designed to be foldable,

compact, lightweight, and modular

“As his supervisor during this internship, I was immediately impressed with Mr. Jewell-Alibhai’s responsiveness and professionalism in addition to his command of engineering design basics and advanced grasp of CAD fundamentals, especially considering his educational status as a first-year undergraduate. He was at first – and throughout his time with us – in the upper echelon of all entry level engineers and designers we have had the pleasure to employ and encounter. I have no doubt that Mr. Jewell-Alibhai will be an asset to any and all future employers and collaborators and, taking into account the well-respected engineering institution at which he is currently studying, will prove to be an exceptional engineer. We would hire him without hesitation and fully recommend that you do the same.”

- Dr. Brandon Conover, CEO Practical Scientific